Vox AC30 cabinets

1960 - 1967

AC30 Twin serial number 6097.

Below, some details relating to the companies contracted by JMI to produce wooden cabinets for the AC30. By and large, all worked to a general specification: finger-jointed 3/4" birch plywood for top; 1/2" for bottom and sides. Sides were thickened at front with a 1/4" strip to match the top.

Up to around serial number 5300, that is to say, mid 1962, the 1/2" bottom panel was not thickened at front. From mid 1962, top, sides, and bottom are generally all 3/4" at front.

Other requirements: two channels around the cabinet for the gold string, 1/8" wide and 1 3/8" from the outer edges; baffles 3/4" thick; back panels and slider boards 3/8" thick; supports for the slider board such that the distance between the upper surface and the bottom of the cabinet top was 5 1/2"; three slots for vents on the cabinet's top. Lower and upper back boards are both fixed with six screws.

There is no such thing (in terms of known survivals) as a "thin-edged" or "thin-lip" AC30, though we do have "thin-edged" AC10s, AC15s, AC50s, AC80/100s, Defiants and Supremes. The boxes of all these models were made more substantial (thicker sides and tops), however, as production proceeded, AC50s, AC80/100s, Defiants and Supremes within a few months of release.

A 3/4" thickness for the top and 1/2" for sides was evidently simply the required minimum for AC30 boxes. In some instances, the wood can be thicker.

In terms of design considerations, it may be useful to include this from the new page on handlesL - Note in the image below that the holes for the end handles lie just inside the lines of piping. Simply good luck? Or were the channels for the piping arranged (when the split-front cabs were being designed in late 1960) in such a way as to allow room for the fixing points? The handles were purchased by JMI "off the shelf". No point putting the piping in only to find that four screw holes punctured it.

Serial number unknown, late 1962 / early 1963.

Aside from cosmetics, the main woodworking requirement that changed was the form of the cabinet back boards. From 1960 to around mid 1963 these had square corners. Thereafter radiused corners were brought in (to match the radiused corners of the front), the change having taken place around serial number 7300. From late 1963, Gla-Rev used chipboard ("particle board") for the baffles of its AC30 Twin cabinets. Super Twin speaker cabinets, however, always have baffles of solid birch ply.

To date no maker's sticker or mark has turned up in an AC30. There are such things, however, in the cabinets made by Heslop and Co. for solid state amplifiers; and in AC100 amplifier section and speaker cabinets (Gla-Rev). See the examples below. Chalked marks inside cabinets are common. Sometimes they are the the mark of the person who made the cabinet ready for use (adding the grille cloth etc.); others are marks to ensure that a cabinet and its back boards could always be matched up if they got separated in the finishing process. Very often boards from one cab - especially those produced by Gla-Rev - will not fit another correctly.

Below, pictures of the interior face of a back board from a beige (fawn) AC30. On the back, in pencil:

"JENNINGS AC. 30. BACKS. 26 3/16" x 8" x 3/8" PLY. 10[0]" - the final zero of "100" being lost when the cut-out for the top-boost controls were made.

It is likely that this board was the top-most one in a stack of 100 in the cabinet maker's works. The screw-holes will have been drilled later to match a particular AC30 cabinet. Thanks to Glen Lambert for the pictures and info.

P.A.Glock and Co.

Up to 1954, the business was based in Belvedere, Erith. Prompted by the need for more space, Glock moved in that year to 1b London Road, Crayford, just over a mile up the road from the Jennings works on Dartford Road. The company remained in Crayford until 1991.

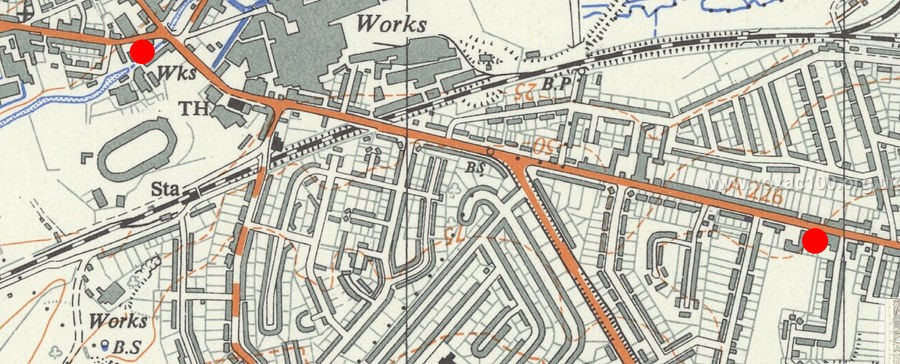

The red dots mark the respective positions of the P.A.Glock works in Crayford (top left), and the Jennings works on Dartford Road (lower right).

1b London Road, marked as "Factory". A little to the north were the Crayford Saw Mills.

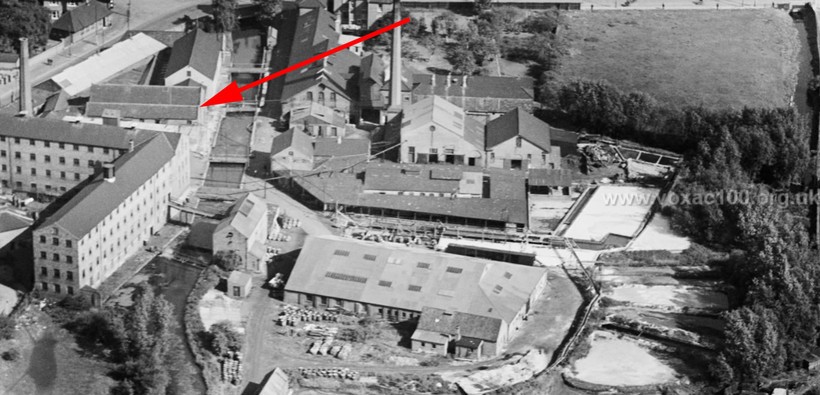

1b London Road, Crayford, photographed from the air in 1934 (i.e. twenty years before Glock moved there).

Gla-Rev (also "Henry Glass" and later Beeskit Ltd)

Some details, albeit sparse for the time being, about "Gla-Rev". The company was formed in the early 1950s, its name an amalgam of those of its founders: Henry Glass and J. Revel.

The business registered at Companies House, London, on 15th August 1952.

"Gla-Rev" produced a wide variety of goods - leather luggage, plastic and vulcanised fibre containers, wooden cabinets and boxes, and so on - "enclosures" of all sorts. There were two factories: one on Selinas Road in Dagenham (East London), constructed c. 1950, the other on Fowler Road, Hainault Industrial Estate (Essex), constructed in 1959.

Revel looked after the smaller items produced by the business; the flamboyant Henry Glass was the driving force behind the commissioning and manufacture of amplifier and speaker cabinets. Glass's Rolls Royce is widely remembered.

Above, the inside of an AC100 amplifier section cabinet from late 1965 / early 1966. "G-R" is "Gla-Rev". The baffle is chipboard.

Gla-Rev cabinets and back boards generally have chalked numbers so that a cab and its boards could be matched up if the latter went astray. Very often boards from one Gla-Rev cab will not fit another. In the late 1960s and early 1970s Gla-Rev made speaker cabinets for HiWatt and Sound City, sometimes trading as "Beeskit Limited" (based in Southend). Glass also traded under his own name, moving his business operations to Ipswich.

AC30 Twin cabinets with chipboard (particle board) baffles - normally indicative of manufacture by "Gla-Rev". These apparently come in around the high 9000s (in terms of serial numbers) - 9986, 9917, and so on into the 14000s. AC50 and AC100 cabinets part-constructed of chipboard sometimes have "G-R" stencilled in white. None, however, has materialised so far in an AC30 cab. The use of chipboard instead of ply is in large part likely to have been a cost-saving measure. Birch plywood was the norm up to this point.

A number of AC30 Twin back panels may have been made of chipboard too - their inner faces covered with vinyl to give additional strength.

Just to note that in company with AC50 speaker cabinets, baffles of AC30 Expanded Frequency cabinets were also made of chipboard. Although the two types of cab were the same size, they were fitted out with speakers differently however.

Below, AC30 Twin serial number 12784. Typical of Gla-Rev's AC30 cabinets in 1964: chipboard baffle, and a single strengthening cleat for bottom and sides. For the most part the cleats are relatively long, occasionally however no more than 3-4 inches.

Serial number 12784T, thick dark grey vinyl (often used instead of basketweave into the 13000s). The corner protectors are later replacements.

Note the long single cleat strengthening bottom and side.

Late 1965 on: when we come to serial numbers in the 21000s, we find not only a Gla-Rev stamp, but back boards with square rather than radiused corners (the latter being the norm from 1964). Whether this means that Gla-Rev had come in anew at this point or was simply changing its normal practice is not clear at the moment.

Serial number 21056T. The Celestion T1088s still have terminals on the frames.

Gla-Rev's contract work for JMI, 1964-1967

The list below is not intended to be exhaustive. Details on smaller amps will be added in due course. Gla-Rev mainly produced amplifier and speaker cabinets for JMI.

The "G-R" stencil - mostly white, sometimes blue - occurs most frequently in AC100, AC50, and 4 and 7-series cabinets. The presence of a chipboard baffle is taken to be a firm indicator of manufacture by "Gla-Rev" inb 1964-1965. Later in 1965 the backboards of its cabs were made with square corners.

1964: AC30 Expanded Frequency cabinets.

1964: batches of AC30 Twin cabinets with chipboard baffles in the serial number range high 9000s into the 14000s . It may be that the company continued to make AC30 cabinets in 1965 and 1966, but constructed entirely of birch ply.

1964: small batches of AC30 Super Twin speaker cabinets with chipboard baffles.

1964-1966 (?): batches of Foundation Bass speaker cabinets. From Spring 1964, back panels regularly made of chipboard through to around 1966. Chipboard baffles occur too though less often. "G-R" stencils have come to light in two cabs so far.

1964-1966 (?): batches of T60 and 2x15" cabinets. Some chipboard back panels. An unknown number of cabs with chipboard baffles too. No "G-R" stencils so far.

1965: considerable numbers of (if not all) AC50 Super Twin speaker cabinets and amplifier section cases. Chipboard baffles for the speaker cabinets. In 1966 birch ply returns. So far, no AC50 from 1966 or later has been spotted with a "G-R" stencil.

Late 1965: AC30 Twin cabinets from around serial number 21000.

1965-1967: AC100 amplifier sections and speaker cabinets. Chipboard used for some amplifier section baffles by late 1965; for speaker cabinet back-boards certainly by mid 1966.

1966: cabinets for the 4 and 7-series amplifiers. Constructed entirely of birch ply. A good spread of instances of the "G-R" stencil.

Heathpoint Timber (from 1965, perhaps 1966)

Based at 533 Rayleigh Road, Thundersley, Essex, only a short distance away from the Gladlyn Works of Timber Techniques / Heslop & Co. (see below). Heathpoint later produced cabinets - late 1960s and 1970s - for HiWatt, Orange, White, and many others. From mid 1968 Heathpoint was probably the single main supplier for "Vox Sound Equipment Limited" and from early 1970 for "Vox Sound Limited". The collapse of Royston Industries in 1967 not only brought down Jennings but Heslop too. By late 1965 / early 1966 Heslop had become an important supplier of cabs for JMI.

533 Rayleigh Road a couple of years ago (from Google Street view). The Works lies behind these buildings. For its position on a map, see the section below on Heslop & Co. Limited.

Ad from "Beat Instrumental" magazine, July 1975 - "... since 1965 ..."..

From 1963 through to late 1964, the Rayleigh Road works belonged to "Thundersley Cabinet Supplies Limited". To date no former member of JMI has recalled any contract with this company.

Notice of incorporation from old Companies House records.

"Daily Mirror", 24th October, 1964. Thundersley placed an advert in almost every Saturday edition of the Mirror from April 1963 through to the end of October '64. Its business was principally self-assembly kitchen units and sheds.

W.D. Hazell Limited (Eltham) - 1963

According to Rodney Angell, who worked for JMI as an amp tester until 1965, Hazell made AC30 cabinets for a short time in 1963. These were not of the highest standard.

Detail from the journal recording the company's registration in 1947.

Below, a couple of cabinets produced with rabbet joints - a relatively simple and cheap method of construction, but not particularly resilient. The hope may have been that the vinyl covering would give the cabinet further strength. Manufacture by Hazell seems likely.

Lower corner of the cabinet of serial number 7521.

.Cabinet of serial number 8267. Full birch ply construction, but rabbet-jointed sides.

Whether Hazell was the maker that produced a number of cabs with elabourate though weak finger-joints, needs verifying. Pictures of such a cab - with spectacular fractures - were posted many years on the old Plexi Palace site.

Timber Techniques / Heslop & Co. Limited

There is now a page dedicated to Heslop & Company. As Jim Elyea notes in his book, "Timber Techniques Limited" produced a certain number of cabinets for JMI from April 1964. In 1965 the business was taken over by "Heslop and Co. Limited", a move that made a good deal of sense: in company with JMI, Heslop was a member of the Royston Group of Companies - Heslop from 1961 at the latest, JMI from January 1963. Heslop became an increasingly important supplier of cabinets of all types from late 1965 / early 1966.

Detail from the frontispiece of "The Beacon", Journal of the Royston Group of Companies, 1967.

Timber Techniques Ltd went into liquidation in June 1965, and the company's "Gladlyn Works" in Rayleigh, Essex became Heslop's chief premises. The interior of the Works is pictured in the 1966 issue of "The Beacon", Royston's house magazine.

"Daily Mirror", 27th June, 1964. A poor reproduction, but the company's name and address is legible.

Detail from Ordnance Survey Map TQ8089A - scale 1:2500.

Late in JMI's run of AC30s, a new type of cabinet was introduced, horizontal and vertical crossbars across its baffle instead of the single (vertical) bar of older cabinets. The new-style cabs appear in the 20700s. perhaps a little before - the first definite example is 20705 - and continue into the 23000s (end of JMI production).

General view of a late JMI cab interior.

Also new was the cut-away for the speakers, no longer a gently curving cut, but a long thin section (radiused at top and botttom) removed:

Detail of serial number 22355's cab. The speakers are later replacements, along with the wiring.

Almost all later cabinets, Italian and English made, through to 1973 followed the late JMI style of double crossbar baffle. None, or at least appearently none, adopted the long thin speaker cutaway. That this strange cutaway is not found in post-JMI cabinets suggests that these cabs were manufactured by Heslop. The collapse of the Royston Group in December 1967 precipated not only the end of JMI but the demise of Heslop and parts of Burndept Electronics too. See the new page on Heslop & Company.

Labels

No Heslop label has come to light so far in an AC30 cabinet. There are survivals, however, in solid state amplifier sections (from 1967). Whether Heslop also produced the accompanying speaker cabinets is not known. It may be that those were farmed out to Gla-Rev in Hainault.

Due to the thinner wood used for their sides and bottom, early Supreme amplifier section cabinets were slightly smaller than later ones, as the picture below shows:

In the foreground, the cabinet of Supreme serial number 1058. Behind it a slightly later Supreme cabinet. The later box is 1/2" wider (the boxes are standing on end in the pic. above). It is also 1/4" taller. The reason: the sides and bottoms of early boxes are constructed of 1/2" thick birch ply. The sides and bottoms of VSEL boxes are 3/4" thick.

Defiant serial no. 1198. Heslop sticker dated 15th May 1967.

Dynamic Bass serial number 1135. Heslop sticker dated 12th May 1967.

Taylor (no other details of name)

1965 - slider boards for AC30s and large box AC50s

A number of AC30 and AC50 chassis slider boards were evidently made by the "Taylor-Made" Company - "Woodware" (see the pictures below) presumably being one of its registered ("REGD") trademarks.

No stickers have been found on the sides, bottom or tops of the cabinets themselves.

One also finds the "Taylor-Made" stamp inside the wooden boxes of certain English-made radios, the example a little further below being the Ekco BPT333. Ekco (E.K. Cole Ltd) was based in Southsea.

Whether the "Taylor-Made" boards came with the amps in which they survive, or, conversely, were supplied to Thomas by JMI as replacements for damaged or broken originals, is not known at present.

The underside of the chassis slider board of serial number 19157. Thanks to Eric for the picture.

Slider board in AC50 serial number 3619.

Slider board in AC50 serial number 4424. The date code on the pots "IM" = September '65.

Detail from the Thomas Organ parts list for the AC50 - "Wooden Chassis Shelf". The sheets are available on this page.

Thomas also offered various cabinet parts for the AC30, including slider boards (shelves):

Detail from the Thomas Organ parts list for the AC30 - "Wooden Chassis Shelf". The sheets as a whole can be found on this page, entry for 26th March.

Detail from the picture of the Ekco BPT333 below.